Quality Standards

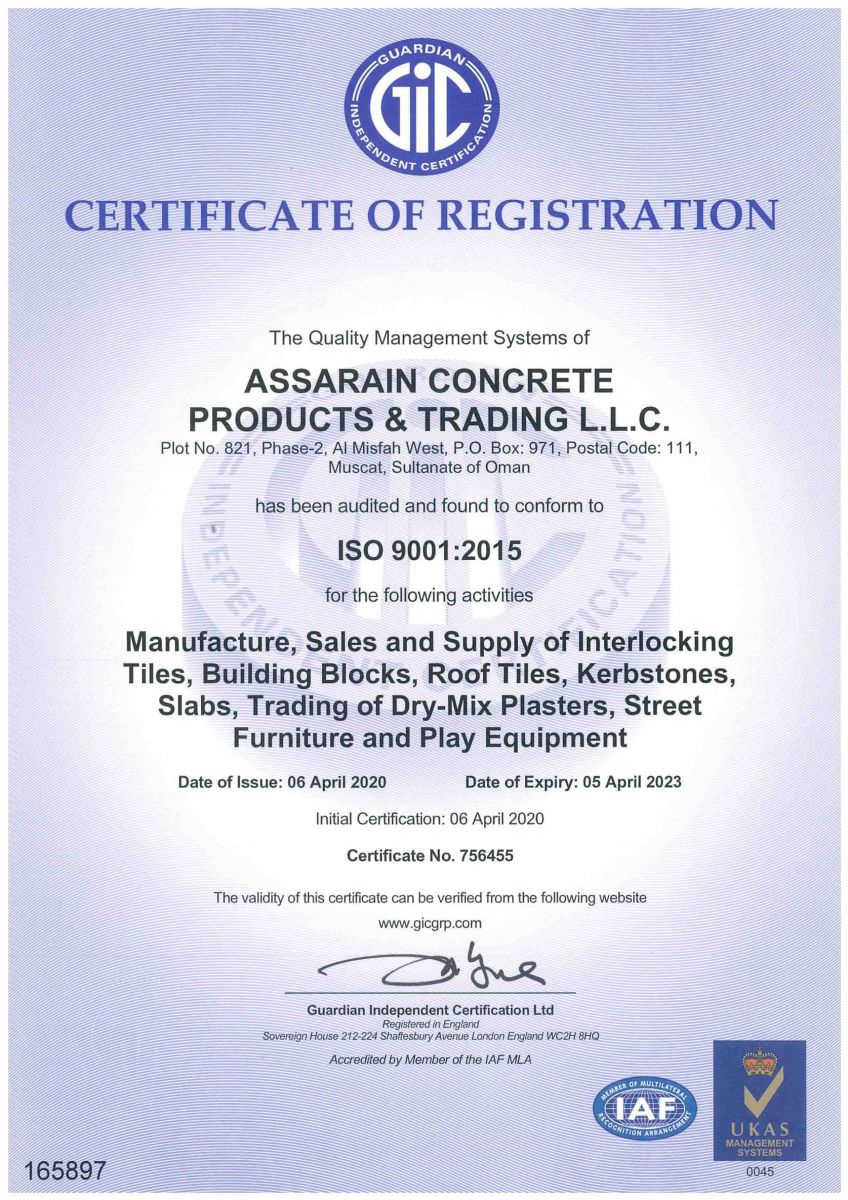

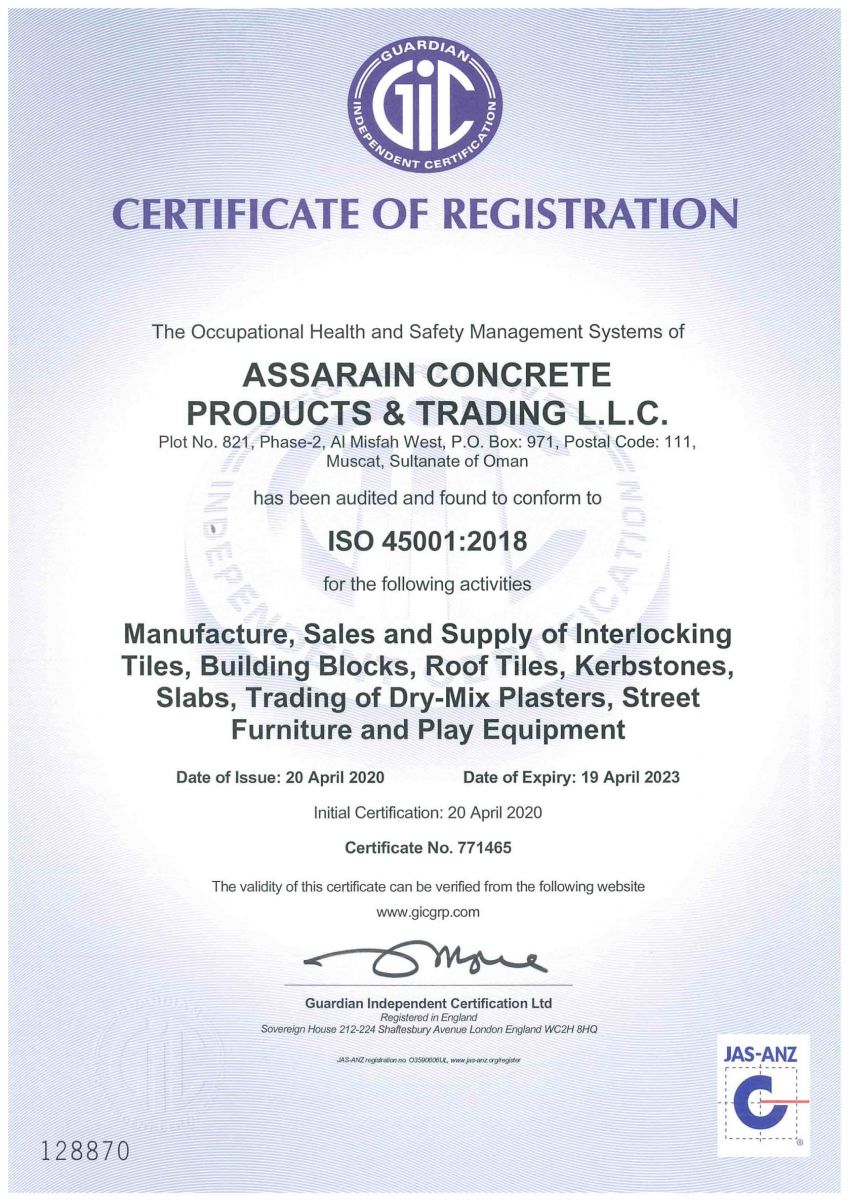

ACP is the only company in Oman among concrete products suppliers that is Integrated Management System (IMS) certified taking up the challenge to prove to the Clients that it is indeed the best company of Oman which has an international recognition of its management procedures, processes and customer focus. The ACP certification describes ACP’s integrated Quality, Environmental and Occupational Health and Safety Management System (QMS / EMS/ OHSAS). It includes ACP’s Quality System policy and describes how it is implemented and sustained throughout the organization.

The purpose of ACP taking a full fledged integrated Quality, Environmental and Occupational Health and Safety Management System certification is to ensure that the product and service quality continues to meet the highest standards demanded by the organization and expected by its customers; and to ensure that ACP’s products, processes, and services are carried out in an environmentally responsible, protective and safe manner.

This apart, it fulfills the minimum requirement of all government organisations; and many other large and responsible companies like Carillion Alawi, CCC, CCC-TAV, Galfar, Al Adrak, STS, PDO etc. and many Consultants like Parsons, Cowi, Cowi Larsen, CES, Khatib Alami, Gulf Engineering, Parsons and many other such similar and demanding Consultancy Organisations. Being certified not only on 9001 but on a fully Integrated Management System consisting of wholistic ISO 9001:2015, 14001:2015 and OHSAS 18001: 2007, helps all such organisations repose more faith in ACP as a supplier.

Why ACP is different from Competitors

- Bench-marking the industry on product quality and range

- Comply with latest BS EN and GSO EN standards

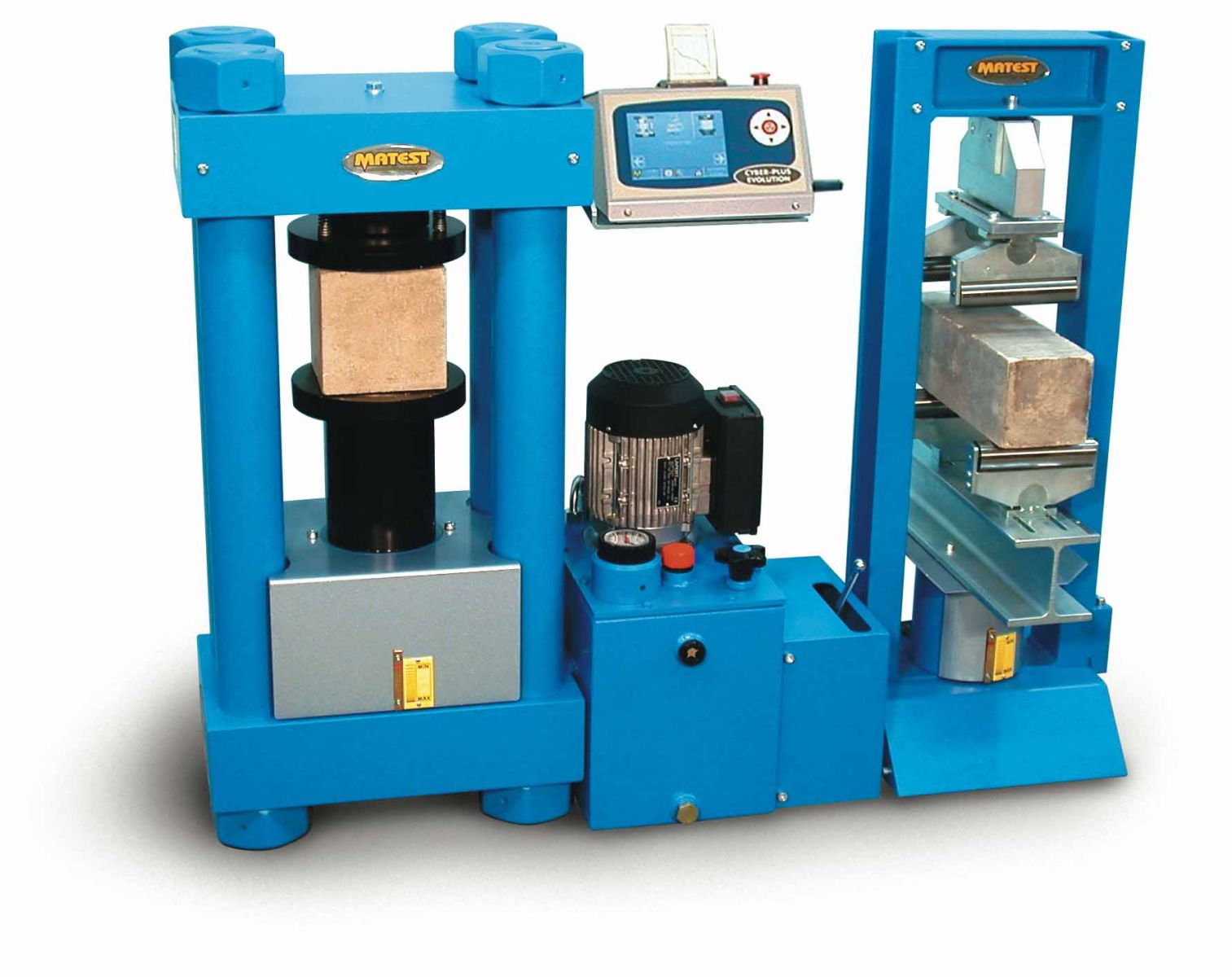

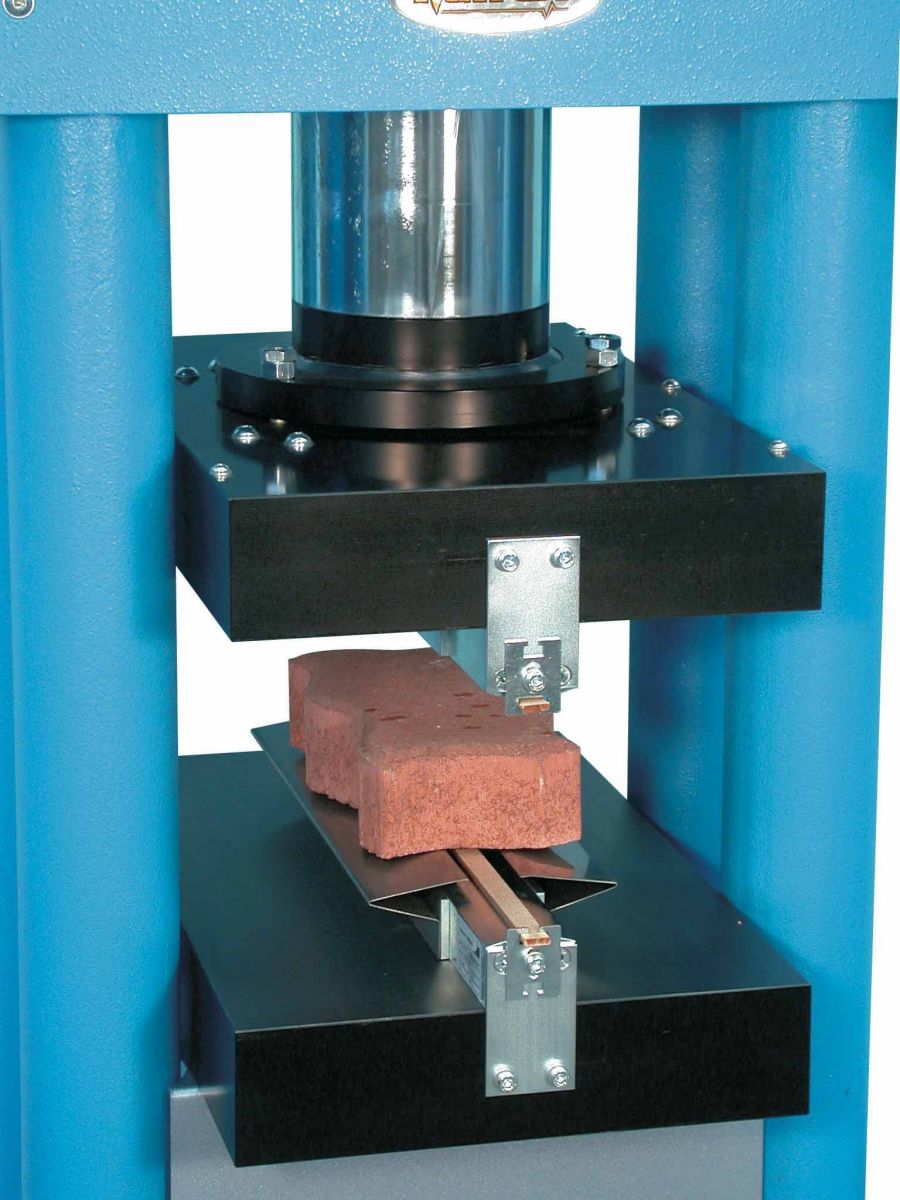

- State of art in house Laboratory facility to conduct all types of product testing & evaluation methods mentioned as per latest BS EN/ GSO EN standards for concrete paving tiles, kerbstones, paving slabs and masonry blocks

- Strict and rigorous in-house testing of raw materials and finished products

- Dedicated team of engineers, supervisors and technicians to ensure the product is manufactured and delivered as per spec

- Steel pallets for production of Interlocking pavers – some Competitors use cheaper options like Wood or Plastic pallets

- Steel pallets transmit 100% vibrational forces directly back to the concrete product

- Automated fully closed Curing chambers with temperature and humidity sensors

- High dimensional accuracy and highly dense products resulting in durability